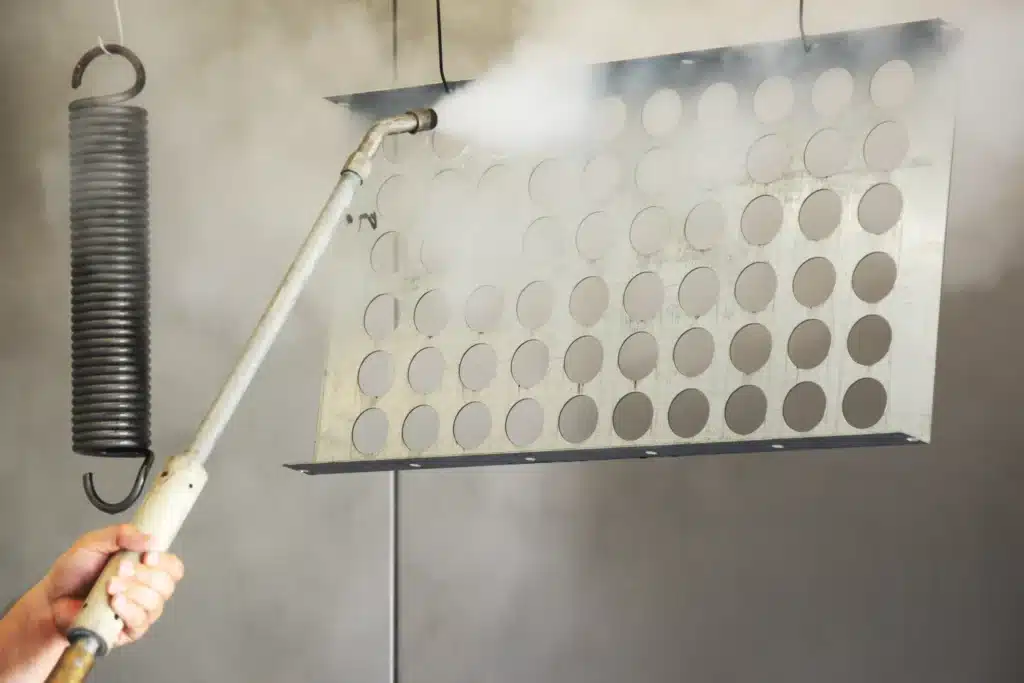

Pre-Treatment Process

At GLPC Fab, we ensure the highest quality finish for our fabricated parts through a meticulous pre-treatment process. This essential step prepares the metal surfaces for powder coating, enhancing durability and adhesion.

Key Features:

Chemical Bath: Our pre-treatment process begins with a comprehensive chemical bath that effectively cleans and de-greases the parts, ensuring they are free from contaminants.

Surface Preparation: The chemical bath also prepares the metal surfaces for powder coating, creating an ideal foundation for a smooth and durable finish.

Aluminum Parts Treatment:

Bonding Agent Application: For aluminum parts, an additional coat of bonding agent is applied.

Baking Process: The bonding agent is baked onto the aluminum parts, significantly increasing the durability and adhesion of the powder coating.

For Aluminum parts we meet spec AAMA 2604 &2605 powder coating.These finishes are resistant to moisture, and weathering.

At GLPC Fab, our commitment to quality starts with our pre-treatment process. By thoroughly preparing each part, we ensure that the final powder-coated finish is not only visually appealing but also long-lasting and resilient.